30 ton chiller for sale

|

30 ton chiller description |

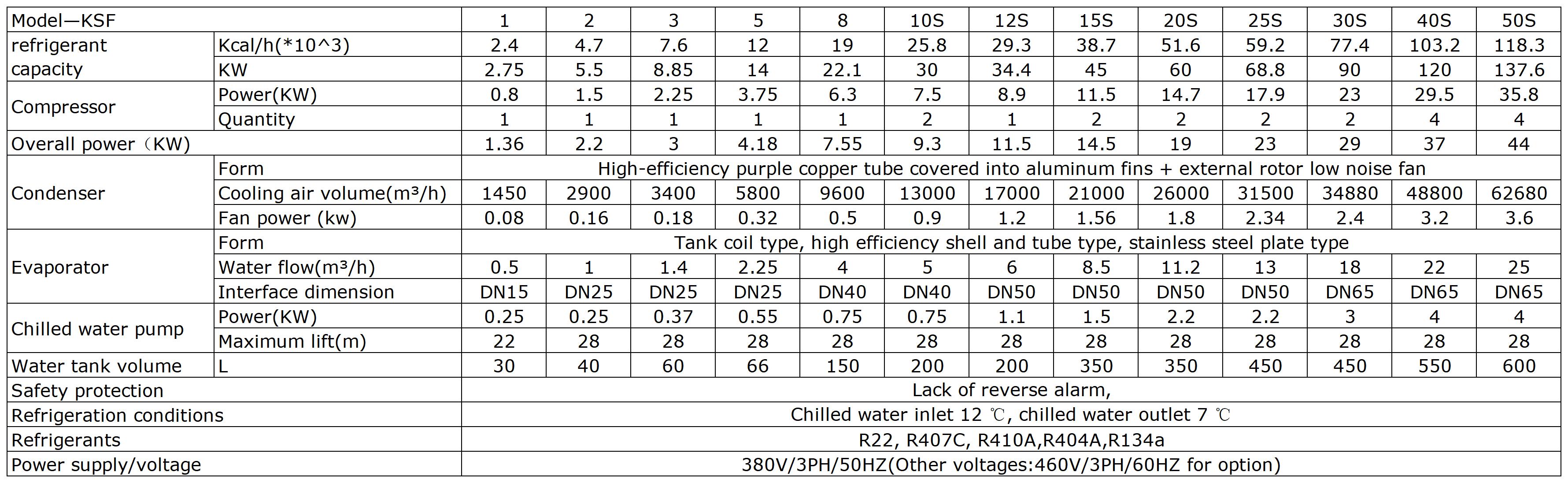

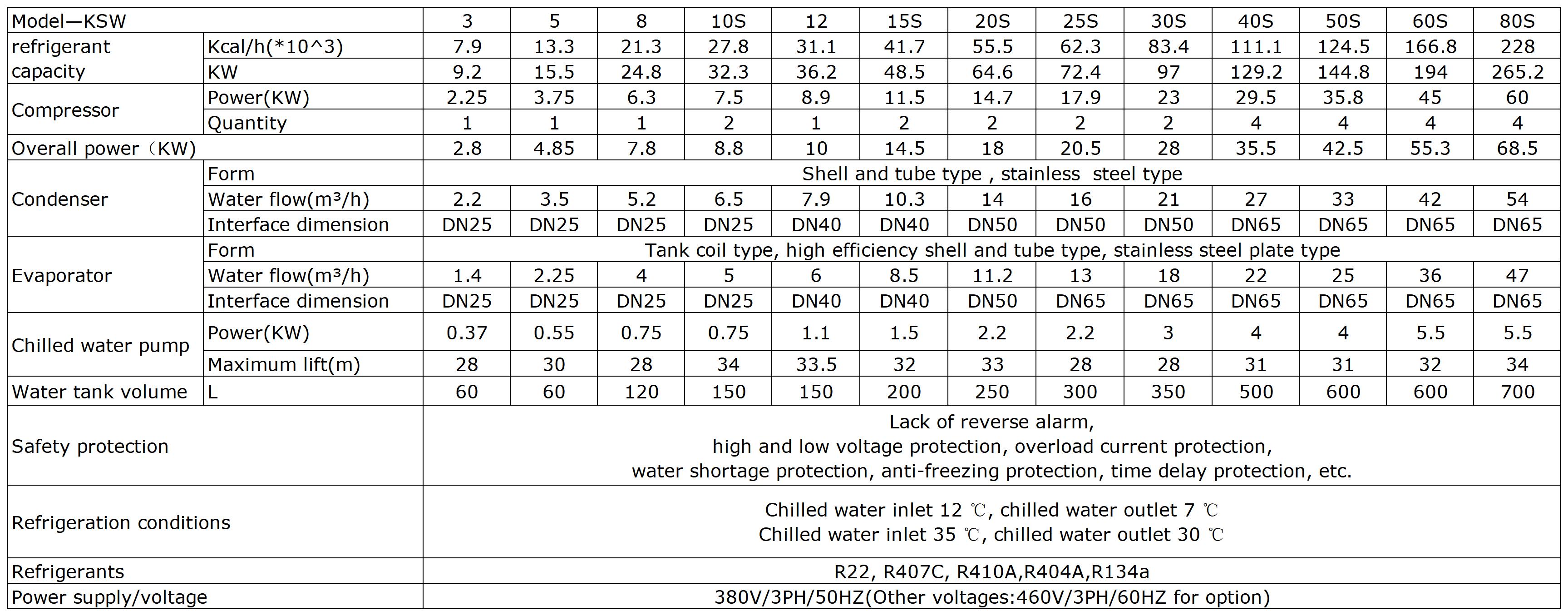

The 30 ton chiller boasts a nominal refrigeration capacity of approximately 105kw and is equipped with essential components such as a screw compressor, coil evaporator, fin condenser, and electronic expansion valve. This 30 ton chiller is adept at providing efficient refrigeration solutions for various industries including plastics, chemicals, vacuum film plating, mixing stations, and laser welding. It utilizes a PID temperature control system known for its precision, responsiveness, stability, and intelligence. Depending on the cooling method, it comes in two variants: 30 ton air cooled chiller and 30 ton water cooled chiller.

The 30 ton air cooled chiller features an integrated structure with a built-in water tank and pump, making installation simpler and more convenient. Just connect the cooling water to the inlet &outlet, power up the equipment, and it's ready for use, particularly suitable for areas with limited water resources. On the other hand, the 30 ton water cooled chiller requires an external cooling water tower. Though installation is relatively complex, it offers higher cooling efficiency.

|

Features of the 30 ton chiller |

●30 ton air cooled chiller: integrated structure, with its own fan, relying on air circulation to the refrigerant heat dissipation

●30 ton water cooled chiller: rely on cooling water to the refrigerant heat dissipation

●Evaporator material: coil type copper tube/SUS304, shell and tube type copper tube/SUS304.

●Condenser: Aluminum alloy micro-channel, purple copper tube sleeve string aluminum sheet

●Conventional temperature control range: 5℃~35℃, if you have a lower temperature demand, kassel can provide customized service according to your requirements.

●PID all-digital intelligent temperature control: PID control system can accurately adjust the temperature of the control system according to the real-time temperature feedback signal, so as to realize high-precision temperature control.

The precision of temperature control is as high as ±1℃, which meets the strict requirements for temperature control in many application scenarios.

●Adopt the computerized version of well-known brands such as Bump, Schneider, etc., and electrical control components.

| Technical Specification |

Technical Specification

Kassel offers customised products according to customer requirements: cooling capacity, explosion-proof models, high precision, other special requirements, etc.