10 ton chiller price

| 10 ton water chiller description |

The nominal cooling capacity of the 10 ton chiller is around 35kw, and the equipment adopts two compressors, which can be used separately or together;

The refrigeration system can be flexibly adjusted according to the actual cooling load demand, improving the performance and efficiency of the system and increasing the maintainability and fault tolerance of the system;

10 ton chiller is suitable for textile, injection molding processing, mixing station, new energy testing, and other fields.

In the new energy industry, the chiller plays a vital role, especially in the hydrogen fuel engine test and test, the reaction will produce a lot of heat energy. By configuring a 10 ton chiller, you can ensure that the test bench is always kept within the appropriate temperature range, which not only extends the service life of the test bench but also improves the overall test results, making it an ideal cooling solution for the new energy industry.

|

Features of the 10 ton chiller |

●Adopting finned heat exchanger, the heat exchanger area is 25%~30% larger than normal heat exchanger, which can work normally even in harsh environment.

● Product type: 10 ton air cooled chiller, 10 ton water chiller

●Adopting an electronic expansion valve for pressure reduction and throttling, it can precisely adjust the flow of refrigerant, with a higher energy efficiency ratio.

●Liquid level sensor: it can monitor the level of lubricant in real time, when there is insufficient lubricant or oil leakage in the refrigeration system, the liquid level sensor will take corresponding measures to prevent oil leakage from occurring, so as to prolong the service life of the compressor.

●The 10 ton water chiller complies with GB150, GB151, TB/T4750-2003 standards, suitable for sea and air transport.

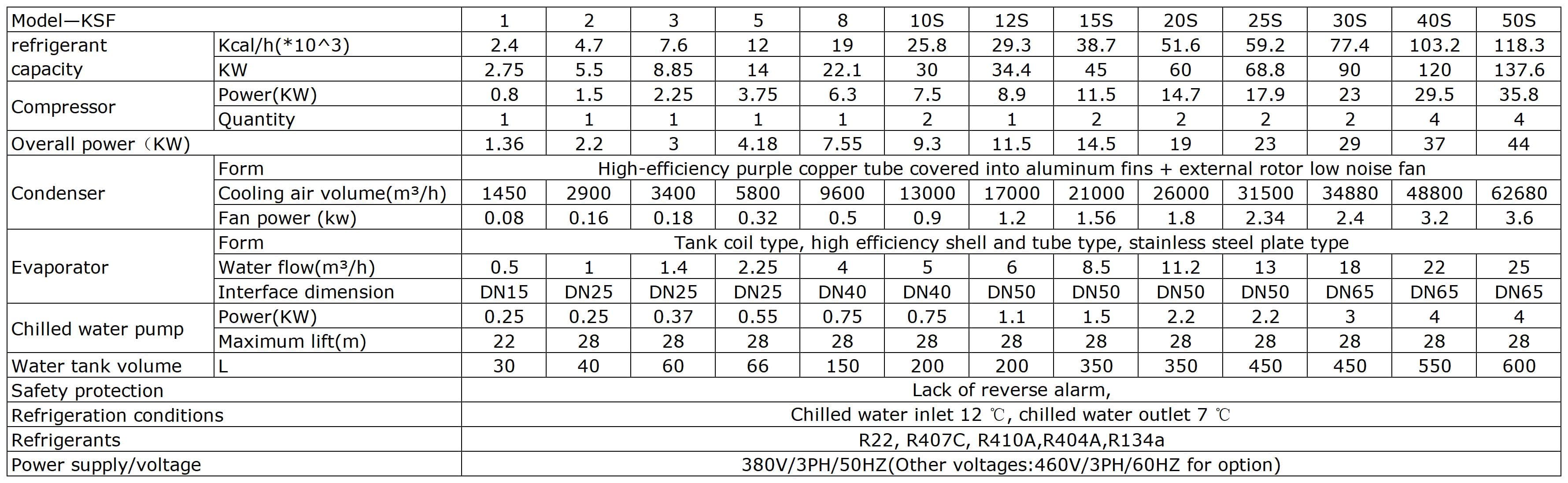

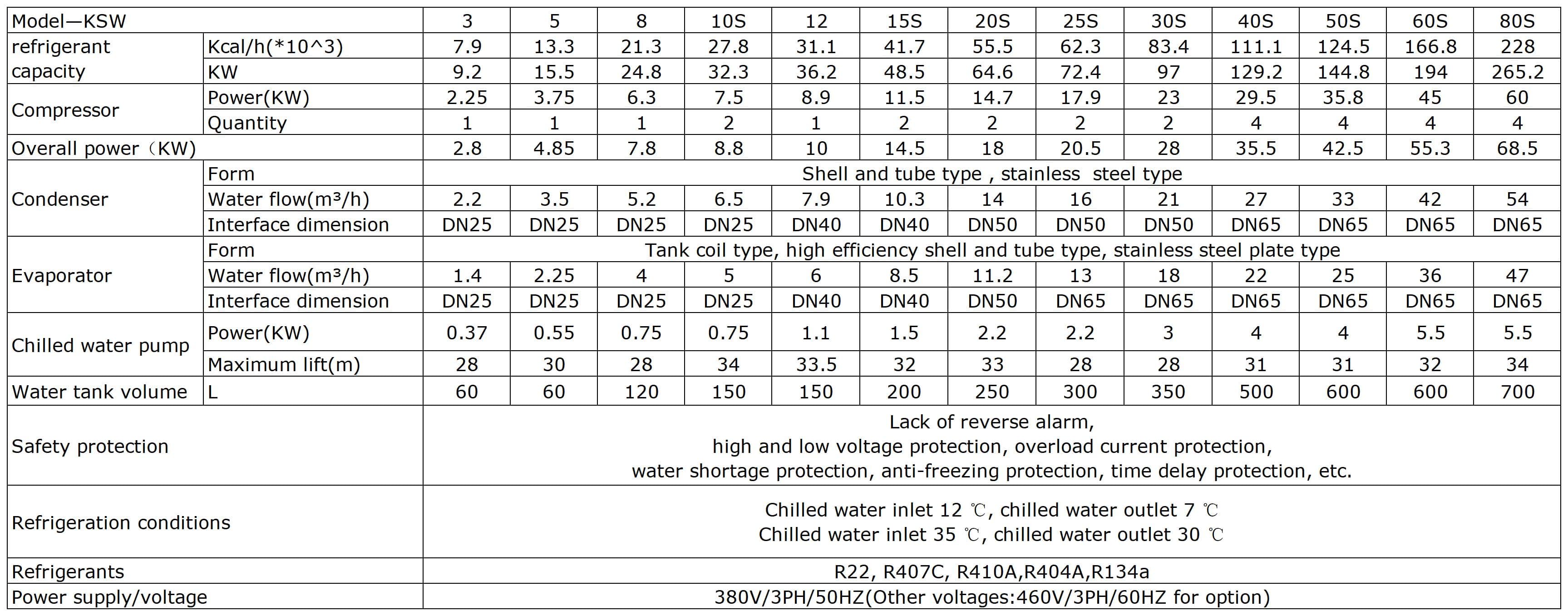

| Technical Specification |

Technical Specification

Kassel offers customised products according to customer requirements: cooling capacity, explosion-proof models, high precision, other special requirements, etc.

Kassel offers customised products according to customer requirements: cooling capacity, explosion-proof models, high precision, other special requirements, etc.